Vibration Isolation Systems are becoming increasingly important in various industries and applications, and one revolutionary advancement in this field is the Vibration Isolation System. This cutting-edge technology Seismic Vibration Isolators offers a unique approach to isolating and minimizing vibrations, providing numerous benefits to various systems and equipment. In this article, we will explore how the Revolutionary Vibration Isolation System works and its numerous benefits in different industries and applications.

The Revolutionary Vibration Isolation System works by utilizing advanced technology to effectively isolate and dampen vibrations in various applications. It typically consists of specially designed components such as isolators, dampers, and mounting systems to minimize the transmission of vibrations from machinery or equipment to its surroundings. This system offers numerous benefits, including reduced noise levels, improved equipment performance and longevity, enhanced safety, and a more comfortable working environment. It is particularly useful in industrial settings where excessive vibrations can lead to equipment malfunction, structural damage, and health hazards for workers. Additionally, the Revolutionary Vibration Isolation System can help optimize production processes and Spring Isolators minimize maintenance costs. Overall, this innovative technology is a crucial solution for controlling vibrations and ensuring the smooth operation of machinery and equipment across a wide range of industries.

The Revolutionary Vibration Isolation System works by employing advanced technology to effectively isolate and dampen vibrations in various applications. It typically consists of specially designed components such as isolators, dampers, and mounting systems to minimize the transmission of vibrations from machinery or equipment to its surroundings. This system offers numerous benefits, including reduced AMC Spring Isolators noise levels, improved equipment performance and longevity, enhanced safety, and a more comfortable working environment. It is particularly useful in industrial settings where excessive vibrations can lead to equipment malfunction, structural damage, and health hazards for workers. Additionally, the Revolutionary Vibration Isolation System can help optimize production processes and minimize maintenance costs. Overall, this innovative technology is a crucial solution for controlling vibrations and ensuring the smooth operation of machinery and equipment across a wide range of industries.

Understanding the Importance of Vibration Isolation System in Machinery

Vibration isolation systems in machinery are crucial for several reasons. First, they improve the longevity and reliability of the machinery by reducing the wear and tear caused by vibrations. Additionally, they help to minimize noise and structural damage to the surrounding environment. Vibration isolation systems also enhance worker safety by reducing the potential for harmful exposure to vibrations. Moreover, these systems can improve the overall performance and precision of the machinery by minimizing unwanted movement and oscillations. Overall, understanding the importance of vibration isolation systems in machinery is essential for ensuring the optimal functioning and durability of industrial equipment.

The Role of Vibration Isolation System in Aerospace and Defense

The role of vibration isolation systems in aerospace and defense is crucial for protecting sensitive equipment and components from the damaging effects of vibration and shock. These systems are designed to absorb and dissipate the energy generated by mechanical disturbances, such as engine vibrations, rough landings, or combat conditions. In aerospace and defense applications, vibration isolation systems are used to protect sensitive instrumentation, avionics, and sensor equipment from the potentially harmful effects of vibration and shock. By isolating these components from the rest of the aircraft or vehicle, the risk of damage or malfunction is significantly reduced. Additionally, vibration isolation systems can also improve the overall performance and reliability of aerospace and defense systems by minimizing the effects of vibration on critical components. This is particularly important in applications where precision and accuracy are essential, such as targeting systems, navigation equipment, and communication devices. Overall, the role of vibration isolation systems in aerospace and defense is to ensure the safe and effective operation of critical equipment and components in challenging and high-stress environments. These systems play a vital role in protecting assets, improving performance, and enhancing overall mission success.

Advantages of Using Vibration Isolation System in Research Laboratories

Vibration isolation systems in research laboratories can provide numerous advantages. They can help protect sensitive equipment from external disturbances and ensure accurate and reliable experimental results. These systems also contribute to a more stable working environment, reducing the risk of equipment damage or failure. Additionally, vibration isolation systems can improve the overall productivity and efficiency of research activities by creating a more controlled and precise testing environment. Overall, the use of vibration isolation systems can greatly enhance the quality and reliability of research conducted in laboratories.

Choosing the Right Vibration Isolation System for Your Application

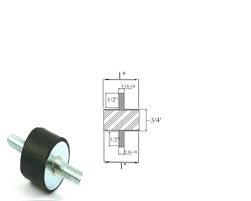

Vibration isolation systems are crucial for protecting sensitive equipment and machinery from the damaging effects of vibrations. When choosing the right vibration isolation system for your application, it's important to consider factors such as the type and level of vibration, the weight and size of the equipment, the mounting capabilities, and the environmental conditions. There are various types of isolation systems available, including air springs, elastomeric mounts, and active control systems. Each type has its own strengths and limitations, so it's essential to carefully evaluate your specific requirements before making a decision. It's also important to consider the frequency range of the vibrations, as well as any potential resonance issues. Additionally, factors such as the need for stability, precision, and ease of installation should also be taken into account. Consulting with a professional vibration control engineer or supplier can be extremely helpful in determining the most suitable isolation system for your application. They can provide expertise in selecting the right type of isolation system and in ensuring that it is properly installed for optimal performance. Ultimately, choosing the right vibration isolation system for your application requires a thorough understanding of your specific needs and careful consideration of the available options. By taking the time to evaluate all relevant factors, you can ensure that your equipment is effectively protected from the damaging effects of vibrations.

The Impact of Vibration Isolation System on Medical Imaging Equipment

The Impact of Vibration Isolation System on Medical Imaging Equipment is significant in minimizing image distortion and maintaining the accuracy of medical scans. Vibration can cause blurring and distortion in medical images, affecting the quality and reliability of diagnostic results. Implementing a vibration isolation system helps to mitigate these issues by reducing the impact of external vibrations on sensitive imaging equipment. This ultimately leads to more accurate and reliable medical imaging results, which are crucial for effective diagnosis and treatment planning.

Common Challenges in Designing a Vibration Isolation System

Some common challenges in designing a vibration isolation system include determining the appropriate type of isolation system for the specific application, considering the frequency and amplitude of the vibrations, accounting for potential resonance and amplification of vibrations, balancing the need for isolation with the need for structural support, and ensuring compatibility with other system components. Other challenges may include accounting for environmental factors such as temperature and humidity, addressing any potential sources of interference or cross-talk, and designing for long-term reliability and maintenance. Additionally, cost and space constraints may also present challenges in the design of a vibration isolation system.

Key Considerations for Maintenance and Upkeep of Vibration Isolation System

vibration isolation systems

- Regular inspection and maintenance of all components of the vibration isolation system is essential to ensure its proper functioning. - Monitoring of the isolation system's performance through regular vibration and noise level measurements is necessary to identify any potential issues. - Proper alignment and installation of the isolation system components is crucial to maintain their effectiveness. - Regular cleaning and lubrication of the isolation system's components to prevent any build-up of dirt or debris that could affect their performance. - Regular assessment of the surrounding environment for any potential changes that could impact the performance of the vibration isolation system. - Periodic testing and calibration of the isolation system to ensure that it meets the required performance standards. - Proper training of personnel responsible for the maintenance and upkeep of the vibration isolation system to ensure they have the necessary skills and knowledge to carry out their tasks effectively.

The Future of Vibration Isolation System Technology and Innovation

The future of vibration isolation system technology and innovation is focused on improving the performance and efficiency of isolation systems in a wide range of applications. This includes advancements in materials, design, and control systems to better isolate vibration and reduce the transmission of unwanted noise and motion. Emerging technologies such as active vibration control and adaptive isolation systems are also being developed to provide more effective and adaptable solutions for challenging vibration environments. Additionally, there is a growing emphasis on integrating vibration isolation systems with other technologies, such as IoT and predictive maintenance, to enhance overall system performance and reliability. Overall, the future of vibration isolation system technology is driven by the goal of creating more advanced, adaptive, and efficient solutions for effectively managing vibration and improving the performance of mechanical and structural systems.

In conclusion, the Revolutionary Vibration Isolation System offers a comprehensive solution for reducing unwanted vibrations in various applications. By effectively isolating mechanical equipment and structures from its surroundings, it minimizes the impact of vibrations and enhances the performance and longevity of systems. The benefits of implementing a Vibration Isolation System are clear, and it is evident that this technology is a crucial component in ensuring smooth and efficient operations in a wide range of industries.

See also

https://www.fabreeka.com/products/vibration-isolators/